SKP imaging example of a corroded Zn-plated Fe sample Scanning Probes – Application Note 9

Latest updated: June 13, 2024Abstract

This short application note shows an example of the type of features that can be imaged using SKP. The SKP model sample, which is a Zn-plated Fe disk is used and contrast is associated with the presence of the two dissimilar metals as well as corrosion products and partial etching of the Zn layer.

Introduction

This application note gives a brief overview of the power of the SKP technique. Here we are able to image four different regions of a coating defect.

Experiment

An M470 was configured in SKP mode and a defective zinc coating was mounted and levelled in a TriCellTM. A tungsten probe was brought within approximately 100 µm of the sample surface and the system set to auto- tune the signal; this removes the requirement on the user to perform lock-in amplifier tuning. A sweep-scan area map experiment was then performed over 6 x 6 mm², with a step size of 100 µm.

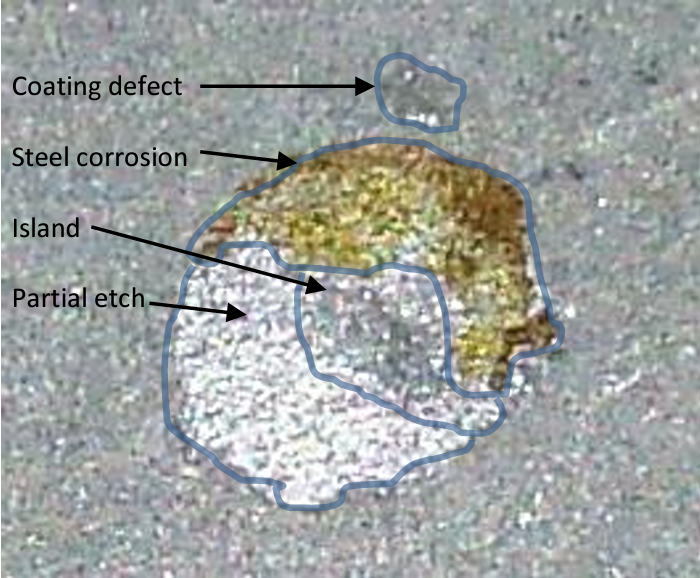

Fig. 1: Sample and approximate scan region outlined in black.

The sample in Fig. 1 is the model SKP sample and is composed of a steel coin coated in a variously worn zinc coating, with a partly acid etched deterioration part.

Results

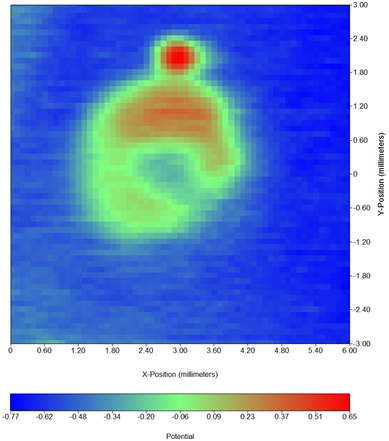

The results of the SKP scan over this sample are seen in Fig. 2.

Fig. 2: SKP area map results.

There are four regions of interest in the SKP map that can be visually identified in Fig. 3.

- Partial etch (Fe + Zn)

- Island (Zn)

- Steel corrosion (Fe hydroxides)

- Coating defect (Fe)

Fig. 3: Zoomed image of defect regions.

If we consider the four different phases on the sample we can establish a relative corrosion potential scale which would look like this:

Zn < Fe + Zn < Fe hydroxides < Fe.

If one looks at the contrast on the SKP map, one can establish the same ranking with the blue color corresponding to the lower Volta potential and red color to the higher Volta potential. We then have:

Coating (Zn) < Island (Zn) < Partial etch (Fe + Zn) < Corroded steel (Fe hydroxides) < Coating defect (Fe).

It follows the same ranking as when considering the corrosion potentials, which confirms that the information obtained with SKP ie. Volta potential or work function difference is proportional to corrosion potentials. This was first demonstrated and proved by Stratmann et al. [1-3]

Additionally, a technical note on how to find the calibration factor between the Volta potentials and the corrosion potentials is available on the Bio-Logic website4.

Conclusion

This short note shows examples of results that can be obtained with the Scanning Kelvin Probe. The sensitivity of this technique allows to identify various type of features: coating defects, a metal in its oxidized state, two different metals in various proportions. Each of these features give different contrasts and values of Volta potentials that follow the corrosion potentials.

References

- M. Stratmann, H. Streckel, Corrosion Science, 1990, 30, 681 – 696

- M. Stratmann, H. Streckel, Corrosion Science, 1990, 30, 697 – 714

- M. Stratmann, H. Streckel, K. T. Kim and S. Crockett, Corrosion Science, 1990, 30, 715 – 734

- SCAN-Lab technical note #3: Relating work function to electrochemical potential