ic-SECM technique for M470.

ic-SECM technique's users can measure distinct surface activity, and surface topography maps

ic-SECM (Intermittent Contact-Scanning Electrochemical Microscopy) is a constant distance Scanning Electrochemical Microscopy (SECM) technique, available on BioLogic’s M470 scanning electrochemical workstation and unique to BioLogic.

The Intermittent Contact-Scanning Electrochemical Microscopy variant of BioLogic’s modular M470 scanning electrochemical workstation. It is a technique unique to BioLogic.

Intermittent Contact-Scanning Electrochemical Microscopy (ic-SECM) is a constant distance Scanning Electrochemical Microscopy (SECM) method. With ic-SECM users can measure distinct surface activity, and surface topography maps. With this single experiment, it is possible to correlate sample features and activity.

The ic-SECM technique is only available on BioLogic’s M470 scanning electrochemical workstation (under exclusive license from the Unwin group at the University of Warwick).

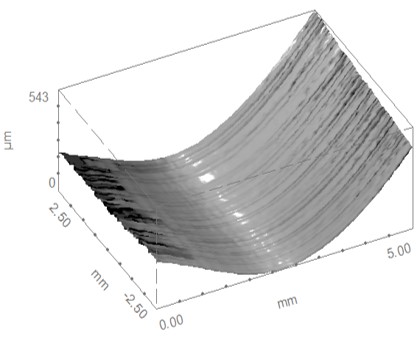

When ic-SECM is used, the probe to sample distance can be maintained over large areas, and even over very rough samples. It has been used to measure extremely flat samples to remove the effect of sample tilt, ensuring the strongest signal throughout the measurement. ic-SECM has found use in battery research, particularly to measure solid-state electrolytes. It can be used in corrosion research, particularly when the sample may be too rough to be investigated by constant height SECM techniques.

Overview: A powerful, versatile, easy to use system

- Measure surface activity and topography at the same time

- Push-button approach to automatically find sample surface

- Sample tilt is no longer a problem

- Available for both dc-SECM and ac-SECM

- Stronger signals

Single constant distance SECM measurement with activity and topography outputs

Constant height SECM is the most popular method of performing SECM, however, because both the sample activity and the probe to sample distance affect the SECM signal, it can be difficult to determine if the measured signal is a result of activity or topography. This can limit the sample types and sizes suitable for measurement by constant height SECM. When ic-SECM is used, however, the topography is tracked throughout the measurement, meaning there is no question that the signal measured is due to sample activity. Using ic-SECM samples which were once off-limits to SECM become possible. ic-SECM opens up the possibility of measuring much larger areas than with traditional measurements because sample tilt is followed, rather than causing detrimental decay to the signal. Furthermore, because topography is measured as a separate output, a correlation between the topography and activity is possible.

A 5.0 mm x 5.0 mm area of the inside of a metal former was measured in 0.01 M H2SO4 using a 25 µm Pt UME biased at 0.65 V.

No approach curve required

In ic-SECM users can perform a push-button approach which automatically finds the sample surface. The push-button approach is based on the mechanical control mechanism used throughout ic-SECM. This means that the ic-SECM approach can be performed even in situations where a standard approach curve could be difficult for even experienced users, for example when the corrosion product of a surface is the redox mediator of interest.

Topography and tilt are no longer an issue

The usefulness of constant height SECM is limited if a sample has large topography changes, and/or large background tilt. In these cases, the difficulty in separating the effect of sample activity and topography are minor in comparison to the topography changes being too large to measure anything but a bulk signal in regions. This can really limit the sample types and sizes suitable for measuring by constant height SECM. When ic-SECM is used, however, samples that were once off-limits to SECM become possible. ic-SECM opens up the possibility of measuring much larger areas than with traditional measurements because sample tilt is followed, rather than causing detrimental decay to the signal. By letting the probe approach closer than would be possible in constant height measurement, ic-SECM has the added advantage that it also results in a stronger signal than would otherwise be possible.

Workstation Software

The Scanning Electrochemical Workstation software provides unique capabilities and interactivity in support of the Model 370 and Model 470 nanometer-resolution scanning probe microscopes. This highly ergonomic software has been designed to facilitate and improve the user experience and render work flows more efficient:

- Improved data analysis, manipulation and interactivity

- Automatic measurement and sequencing functionalities.

Over 40 discrete experiments provided throughout, each with their own individual variations

| Scanning Stage | |

| Scan Range (x,y,z) | 110 mm x 110 mm x 110 mm |

| Minimal Step Size (x,y,z) | 20 nm |

| Positioning | Closed loop positioning, linear, zero hysteresis encoder with direct real-time readout of displacement in x, y, z |

| Linear position encoder resolution | 20 nm |

| Max Scan Speed | 10 mm/s |

| Measurement Resolution | 32-bit decoder @ up to 40 MHz |

| Dimensions | 500 mm (H) x 400 mm (W) x 675 mm (D) |

| Piezo Element (used for ic- control) | |

| Piezo Crystal Extension | 100 µm |

| Vibration Frequency | 80 – 600 Hz |

| Vibration Control | 20 nm – 2 µm Peak to Peak |

| Minimum Increment | 1 nm |

| Piezo drive resolution | 0.095 nm |

| Strain gauge resolution | 3.05 nm |

| Minimum Vibration Resolution | 0.12 nm Calculated (16- bit DAC on 4 µm)

|

| Potentiostat | |

| SP-300 | |

| Compliance Voltage | ±12 V |

| Applied Potential | ±10 V |

| Resolution | 300 µV |

| Measured Potential | ±10 V |

| Resolution | 1.65 µV |

| Current Ranges | 100 pA to 1A |

| Maximum Current | ± 500 mA |

| Current Resolution | 76 aA |

| Floating Capability | Floating Mode |

| Cell Connections | 2, 3, or 4 electrode |

| Scan Rate | 1 µV/s to 200 V/s |

| Modes | Potentiostat, Galvanostat, OCP |

| EIS Capabilities | |

| Frequency Range | 10 µHz to 1 MHz |

| Analyzer Accuracy | 1%, 1° |

| Frequency Resolution | 0.1 nHz |

| General | |

| Available Probes | 10, 15, and 25 µm Platinum |

| Available Experiments | ic-SECM Approach, ic-SECM Area Scan, ic-ac-SECM Area Scan |

How do I use the M470?

Connection of 3300 potentiostats to the cell

Connection of SP-300 potentiostats to the cell

Setting up the probe & building the MicroTriCell

Experimental conditions and set-up

Probe characterization

Sample characterization

Approach experiment on resin (insulator)

Approach experiment on Gold (conductor)

Line Scan and Area Scan

Is there any analysis software available for use with the M470?

What application areas can I use the M470 for?

I see you supply 1 µm probes. Can I use these with the M470?

The following application note relates to 1 µm probes

Can I perform constant distance measurements?

The following application notes relate to distance measurements…

AN#1 – Height tracking with the SKP370 or SKP470 module

AN#2 – SECM height relief with OSP: An application in corrosion

AN#3 – SECM height relief with OSP: an application in sensors

AN#6 – Advantages of the intermittent contact SECM: two examples in corrosion

AN#11 – Measurement of a nano-patterned gold sample by ic-/ac-SECM

AN#13 – Investigation of an interdigitated array electrode using ic-SECM

AN#16 – Intermittent Contact (ic) SECM for relief of major topographic features

TN#14 – Height Tracking Inputs for SKP Investigations