EC-Lab® solutions for coupling with external devices

Latest updated: December 4, 2024Introduction

Nearly all research requires the combination of different devices to get as much information as possible about an experimental in-situ / in-operando setup. Therefore, potentiostat integration, synchronization, and interfacing with other devices are essential for many customers (see partnership page: https://www.biologic.net/partners/).

Requests are varied but they can be grouped into 3 main types:

- Synchronization and/or control of the instrument by the potentiostat’s software.

- Control, and monitoring of all devices in a centralized manner.

- Automation of the processing and export (for security) of the data.

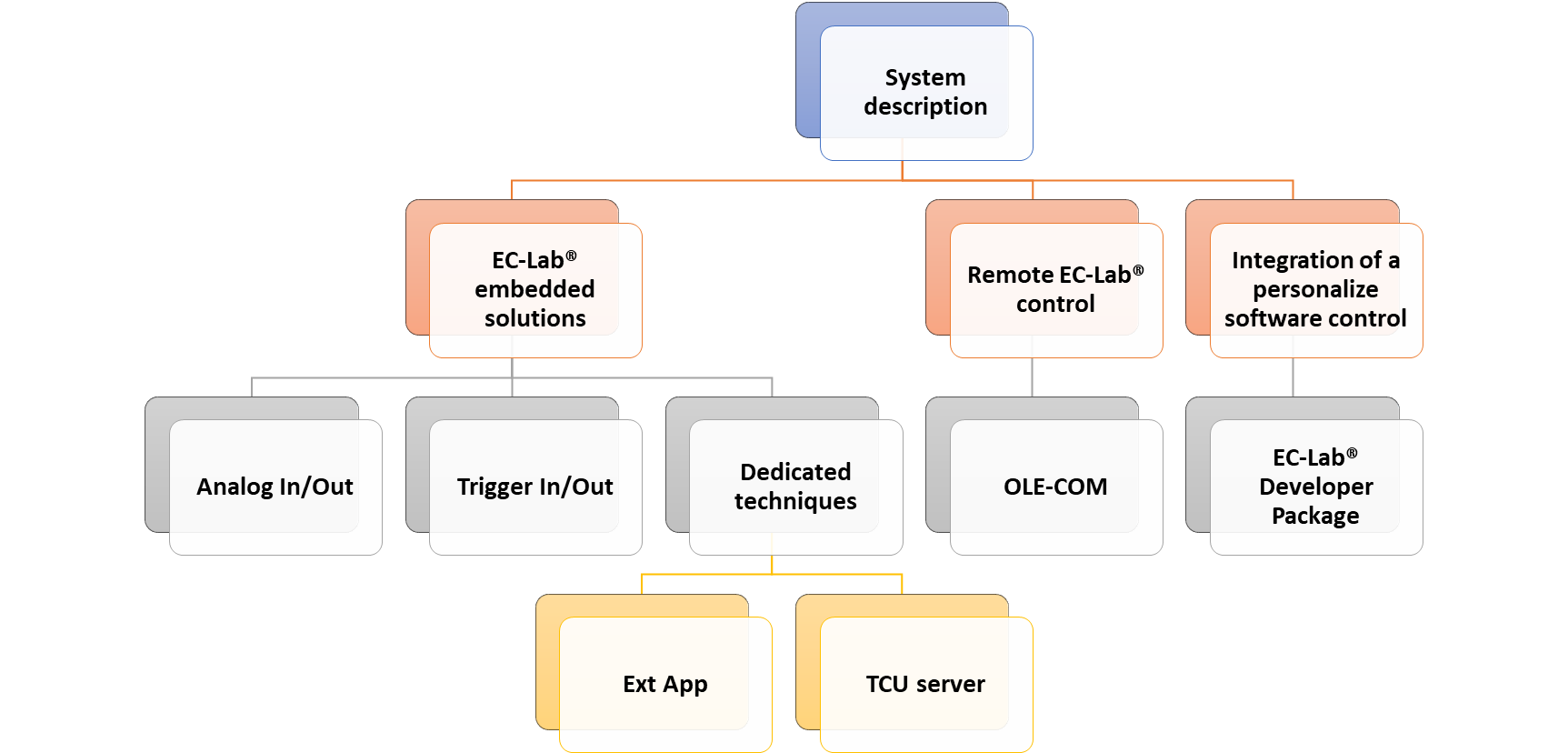

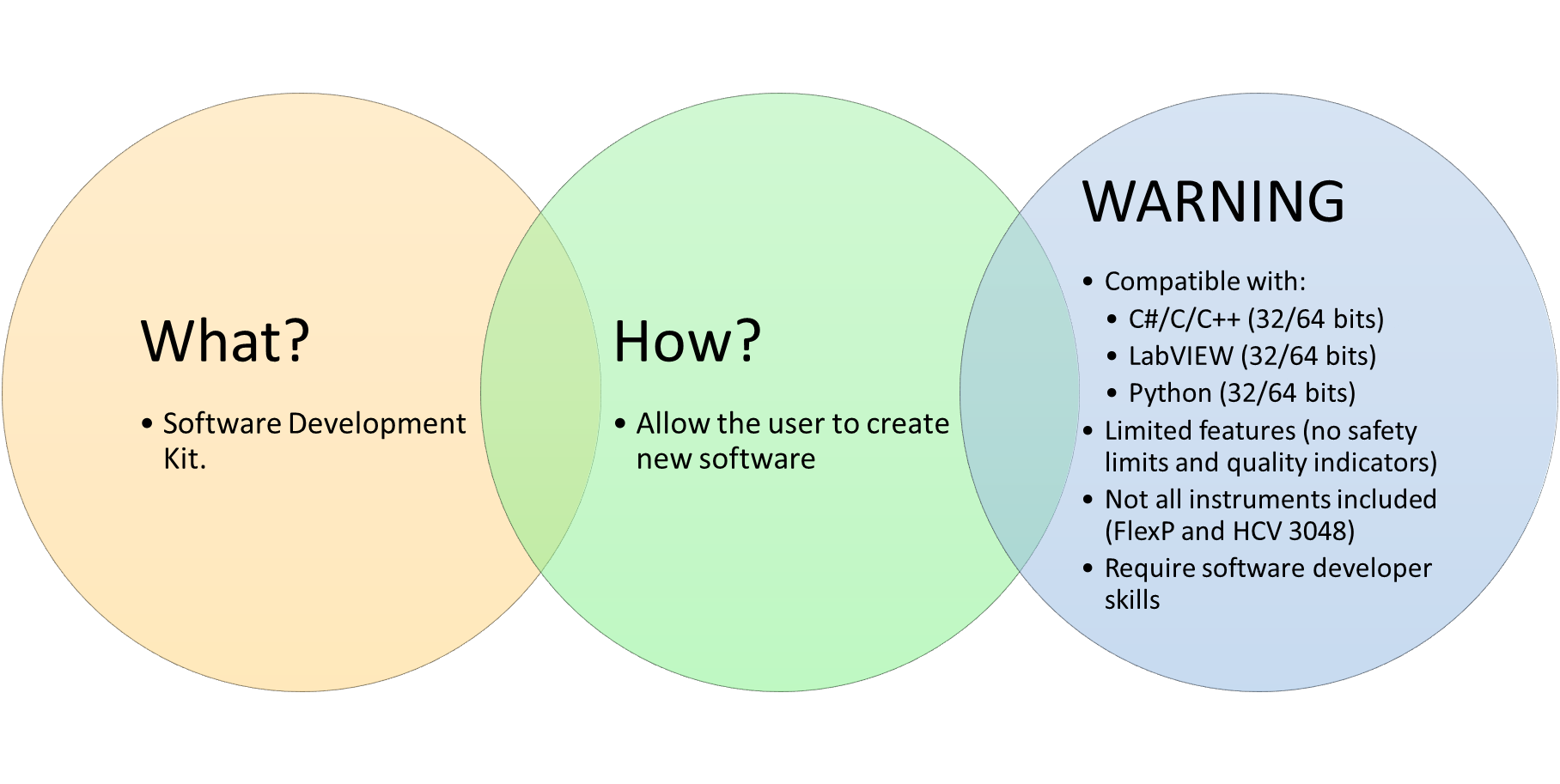

BioLogic has several tools that can help customers to organize/automatize their experiments. We can find tools embedded in EC-Lab® software, as well as more advanced tools that allow either to remotely control EC-lab® software or control the potentiostat in a different customized software:

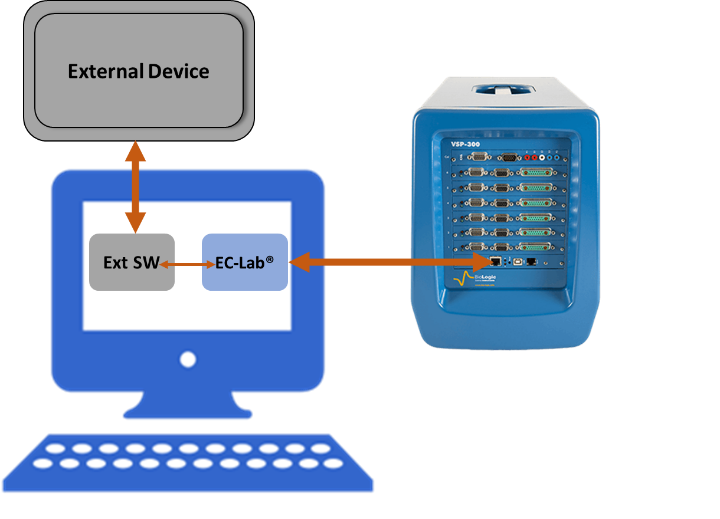

Figure 1: System description of different solutions offered by Biologic for coupling system.

1. EC-Lab® embedded solutions

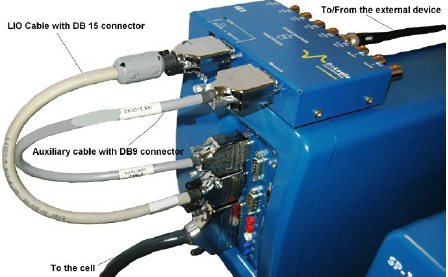

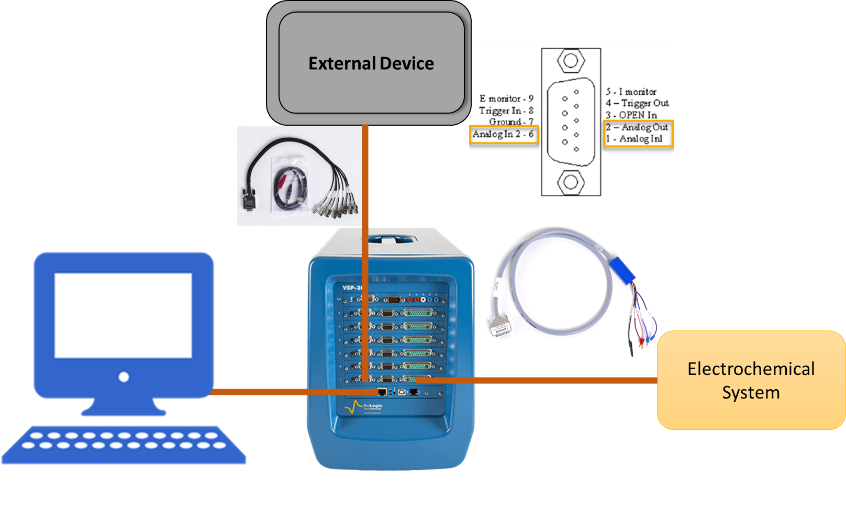

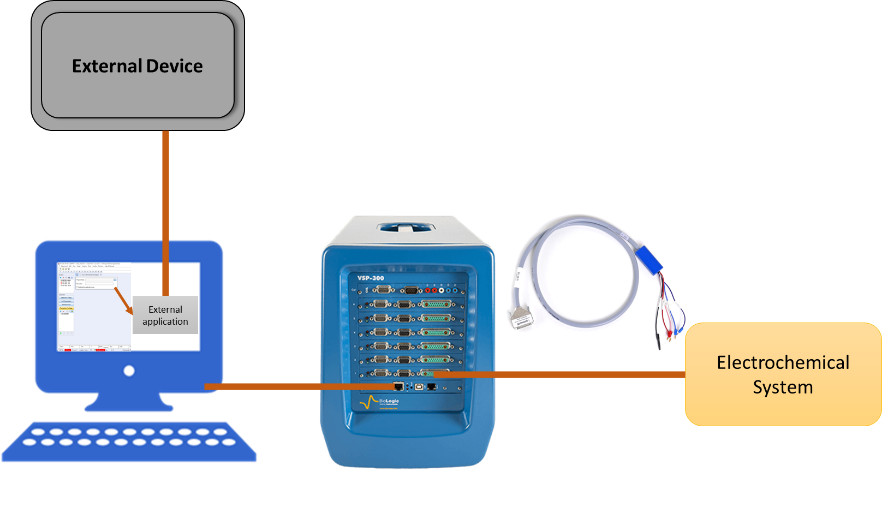

EC-Lab® embedded solutions allow the user to synchronize/control external devices. In many cases, direct connection of the external device to the potentiostat is needed. In this case, Biologic recommends the DB9 cable to facilitate such coupling (see Figure 2).

Figure 2: DB9 connector for communication of potentiostat with external devices [https://www.biologic.net/accessory/external-device-connection/].

If the external device and the cell are grounded, the IS1 isolation module (Figure 3) allows the user to use a channel in floating mode. IS1 can only be used with the Premium range (TN 31: https://www.biologic.net/documents/ec-lab-technical-notes-31-isolation-system-is1-how-and-why/).

Figure 3: IS1 Isolation module connected to a Premium potentiostat.

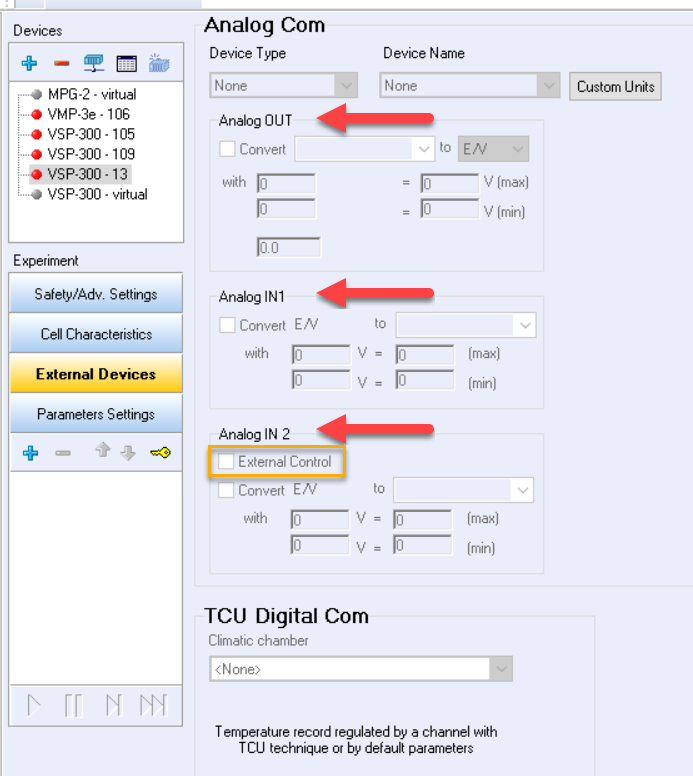

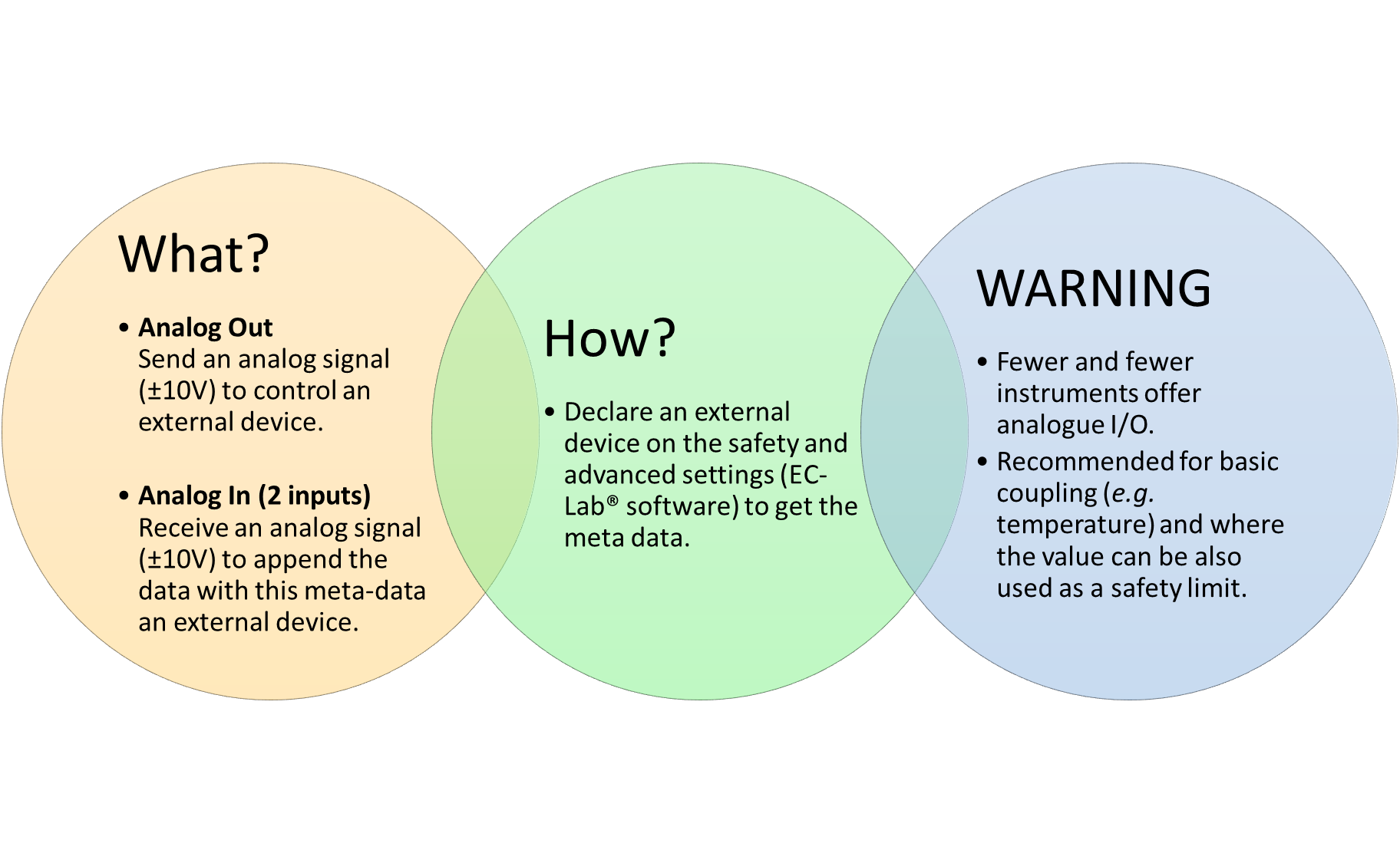

a. Analog In/Out

An external device can be controllable by a potentiostat through the Analog out/in input by using the DB9 connector. Once the device is connected, the configuration can be done by using the “External device section” in the EC-lab® software (see Figure 4).

Figure 4: External device section in EC-Lab® software.

The user must configure the “Analog OUT” to control an external device and “Analog In1” and “Analog In2” inputs to record external signals. Our instruments can control and record analog signals from – 10 to + 10 V. Most of the external devices work in a 0 to + 5 V range. In that case, the external device is passive towards the potentiostat. Some devices are already configured on the list of device types (TN 21: https://www.biologic.net/documents/ec-lab-technical-notes-21-external-device-control-and-recording/).

The external control option is available with EC-Lab® software, which allows the use of an external device to control the potentiostat/galvanostat. In this case, the external device is active towards the potentiostat (TN 25: https://www.biologic.net/documents/ec-lab-technical-notes-25a-control-of-the-potential-current-signal-by-an-external-device-part-i-control-by-a-low-frequency-generator-lfg/). To access to this option, the external device should be connected to the Analog In2 of the DB9 cable. The option must be activated on the external device section in EC-Lab® software.

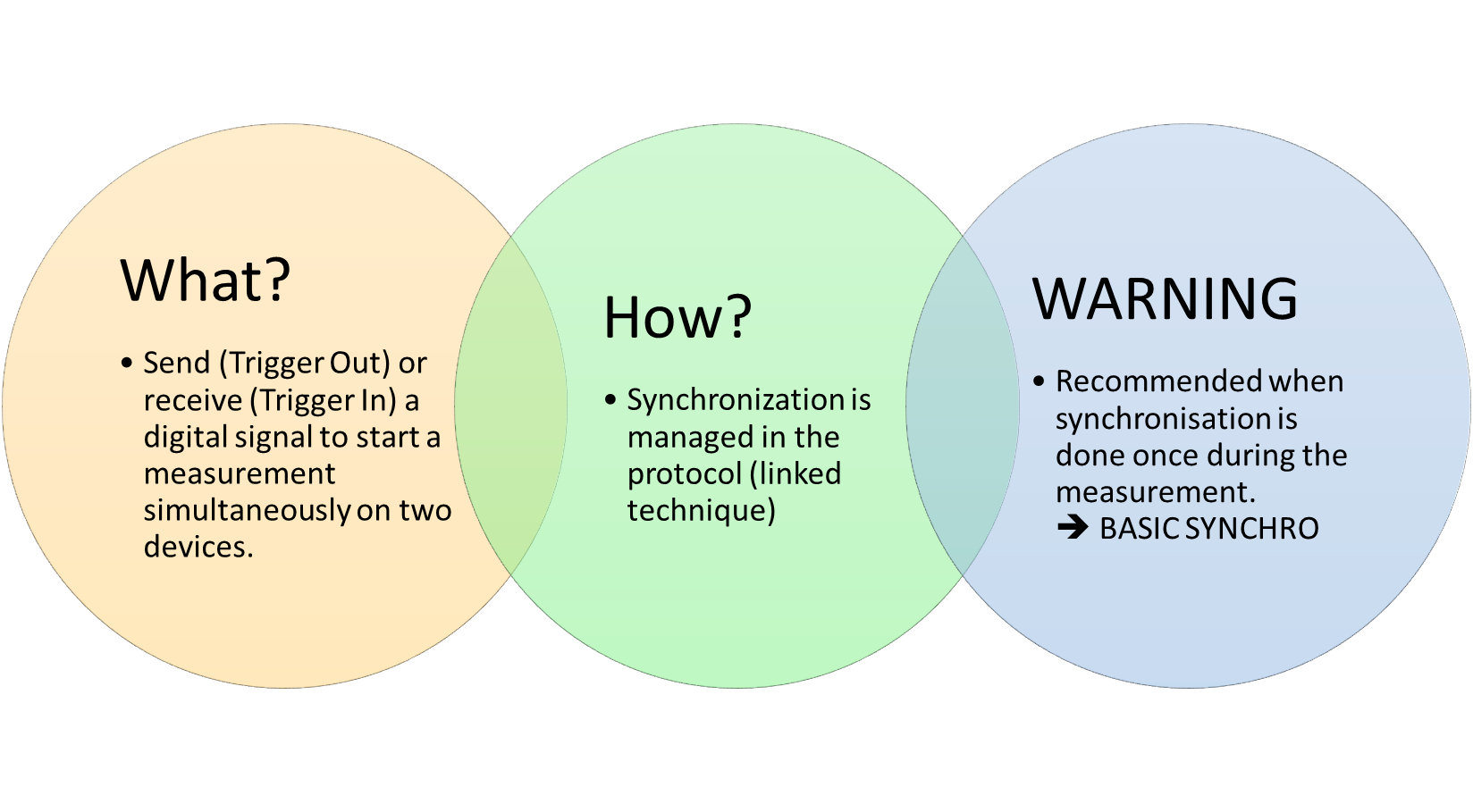

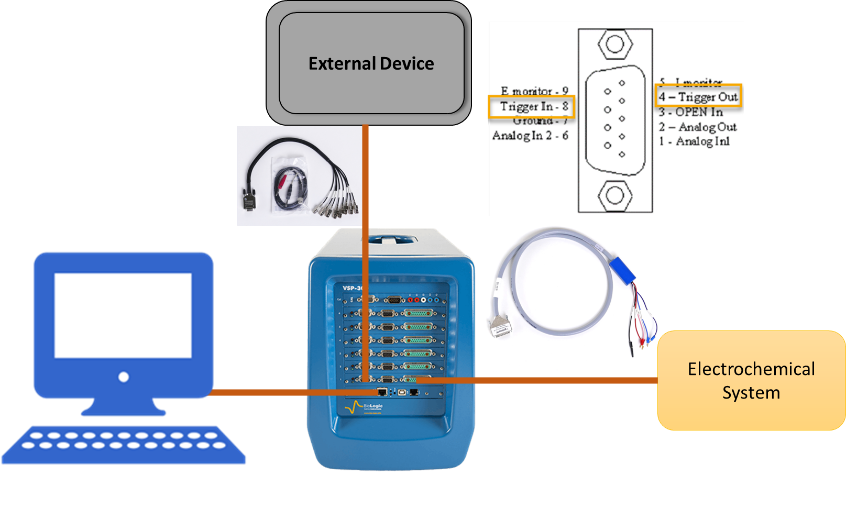

b. Trigger In/Out

Trigger In can be used to start or stop an electrochemistry technique through a TTL (Transistor-Transistor Logic) signal. For this, another instrument must send a trigger to the instrument. Trigger Out can be sent at the experiment’s beginning or end. It is used to start or stop an experiment on another instrument.

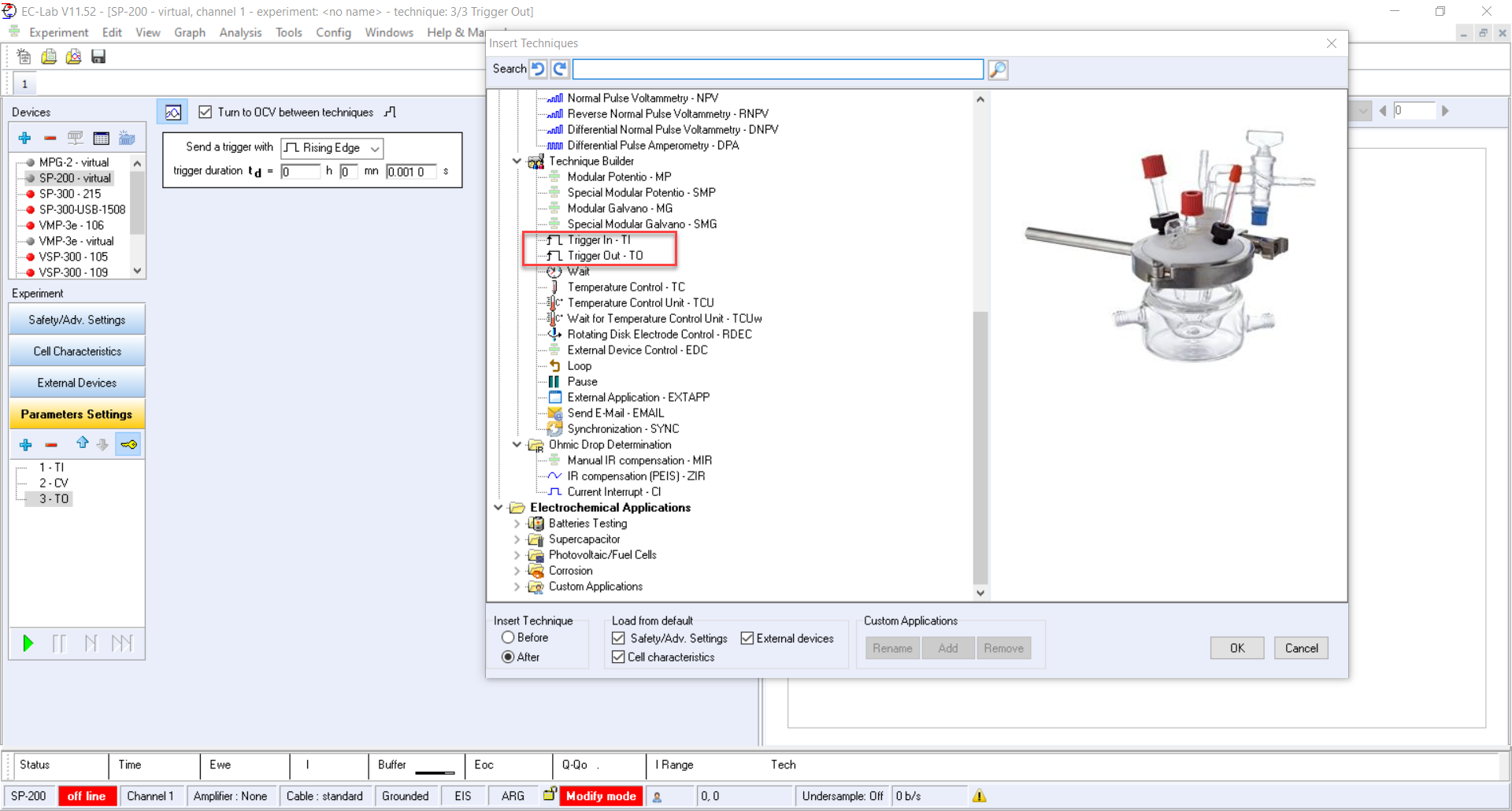

To access this option, an external device should be connected to the Trigger In/Out of the DB9 cable. Trigger In and Trigger Out are techniques programmed into the experiment protocol (Figure 5).

Figure 5: Triger In/Out in EC-Lab® software.

The Trigger signals have high and low levels: + 3.5 V < Trigger high level < + 5 V and 0 V < Trigger low level < 0.8 V.

c. Dedicated techniques

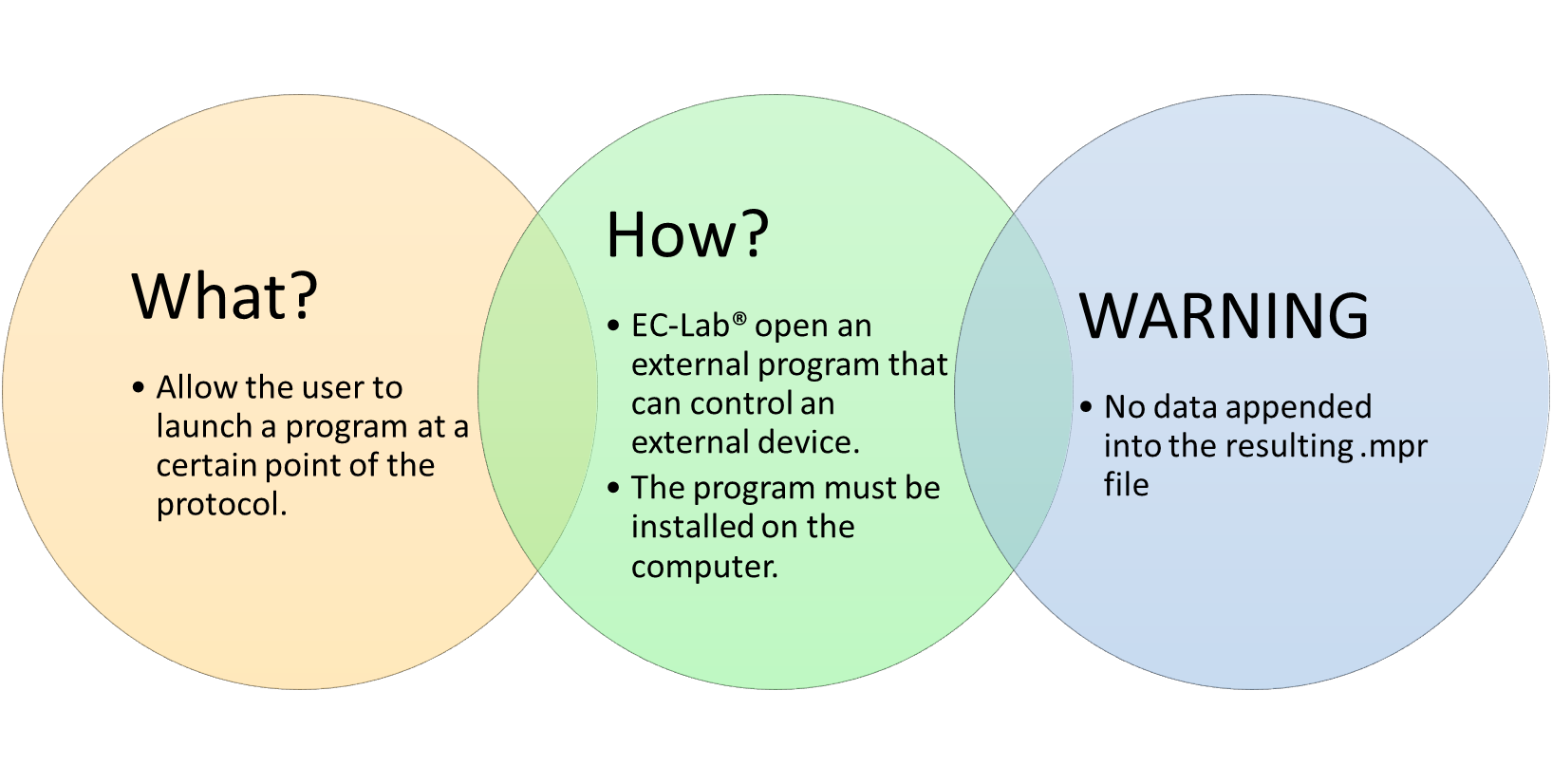

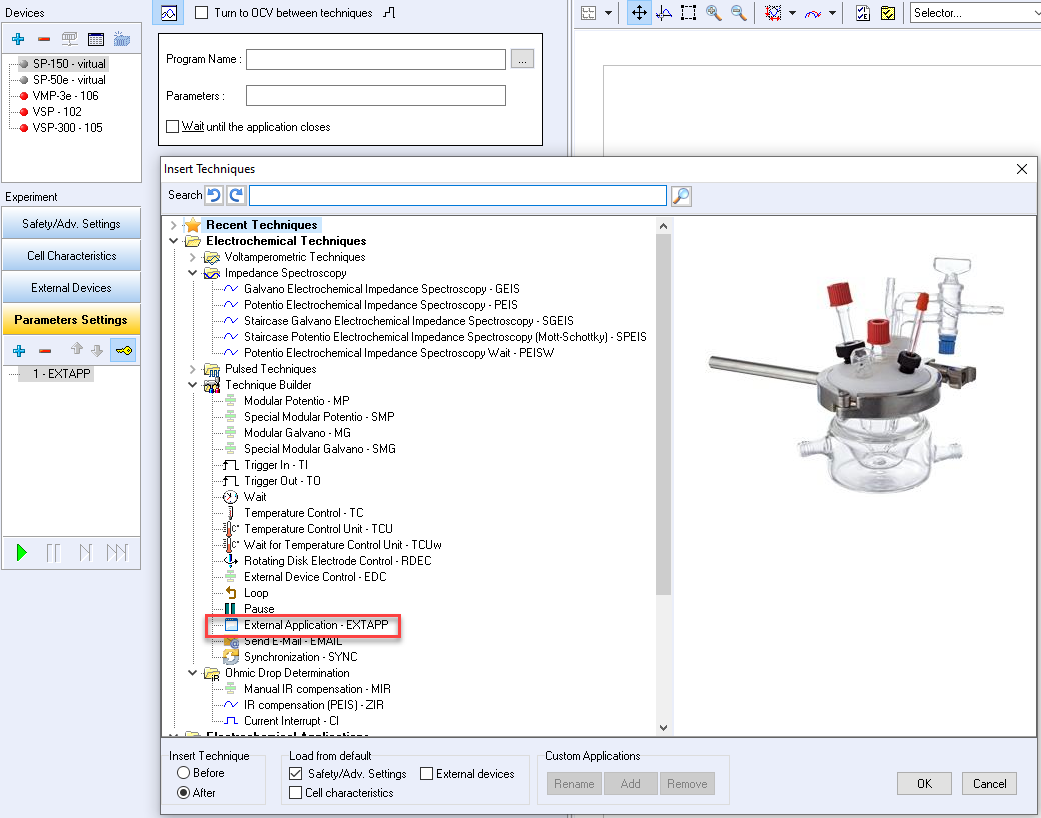

i. Ext App (External Application)

ExtApp is a protocol available in EC-Lab® and BT-Lab® (Figure 6) which allows opening an independent program controlling an external device.

Figure 6: External application technique.

While the EXTAPP technique is applied, the previous control mode remains applied. If the customer wants to shift to OCV mode, the “turn to OCV” option must be enabled. By default, the timeout for this technique is 15 min but it can be changed in the EC-Lab.ini or the BT-Lab.ini file, for EC-Lab® or BT-Lab® software respectively. By selecting the option “Wait until the application closes”, it is possible to wait until this program is closed. Until this time, the experiment turns into Relax mode until the external application is closed. If this box is not ticked the experiment will continue in parallel.

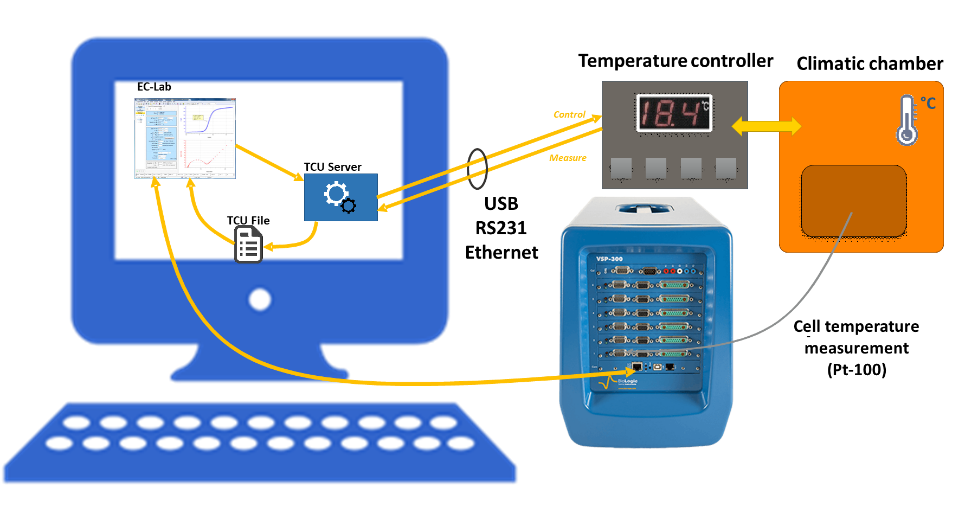

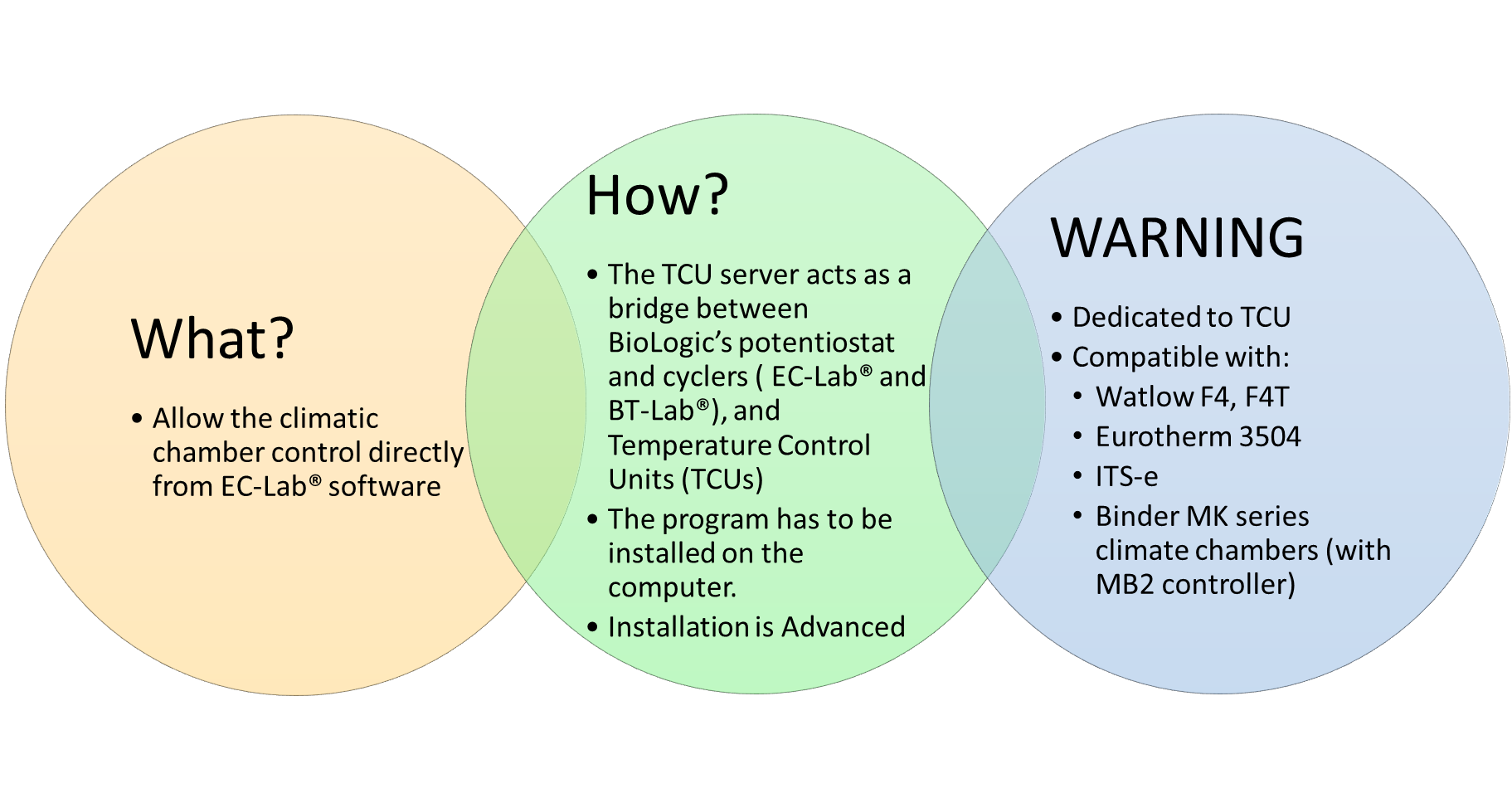

ii. TCU server

Temperature Control Unit protocol allows to control of some climatic chambers through digital communication and the “TCU server” program (separately provided and available in EC/BT-Lab® since the EC/BT-Lab® V11.40 and BT-Lab 1.74).

TCU server software: https://www.biologic.net/support-software/tcu-server/

TCU server manual : https://www.biologic.net/documents/tcu-server-installation-climatic-control-via-ec-lab-biologic-potentiostats/

TCU server video tutorial: https://www.biologic.net/documents/tcu-server-direct-control-of-climate-chambers-via-ec-lab-video-tutorial/

2. Remote EC-Lab® control

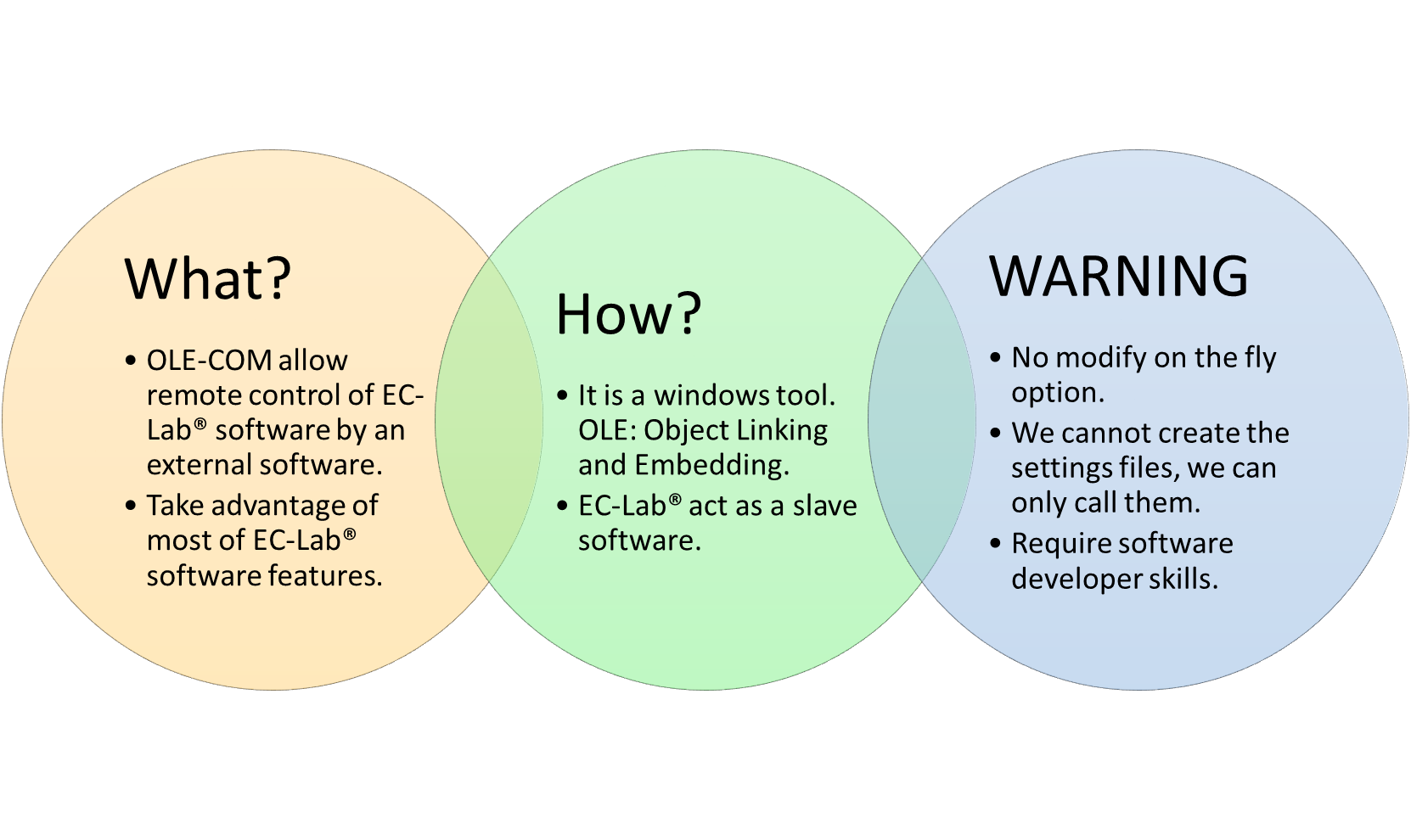

a. OLE-COM

The OLE COM mode allows piloting BT-Lab® or EC-Lab® software from any programming language that supports the OLE COM (e.g. LabView).

By default, BT-Lab® and EC-Lab® are not registered to act as an OLE COM server. This must be done to pilot this software by OLE COM commands.

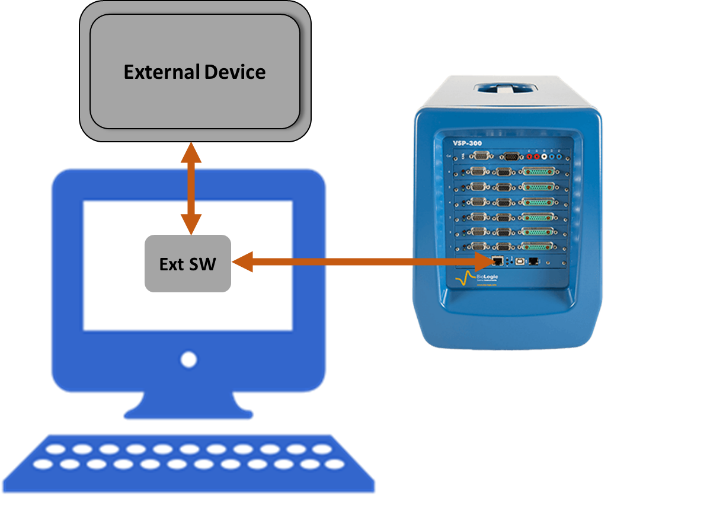

3. Integration of a personalised software control

a. EC-Lab® Developer Package

The EC-Lab® Development Package is intended for software developers who need to integrate BioLogic potentiostats/galvanostats in OEM applications.

The library accommodates some functionality offered by EC-Lab® software:

- Detection of connected instruments,

- Connection/disconnection to the instrument through Ethernet/USB,

- Channels initialization (firmware loading),

- Load techniques on selected channel(s) (OCV, CA, CP, …),

- Start/stop selected channel(s),

- Retrieving data,

EC-Lab® Developer Package: https://www.biologic.net/support-software/ec-lab-oem-development-package/

Related products

Related accessories