How to use XRD for in operando battery analysis

Latest updated: November 15, 2024Introduction

The widespread use of commercial batteries has revolutionized the way we live and work. Portable electronics such as smartphones, laptops, and tablets have become an integral part of our daily lives, and their functionality and convenience are largely dependent on the performance and reliability of the batteries that power them. Electric vehicles are becoming increasingly popular as a more sustainable and environmentally friendly mode of transportation, and their success largely depends on the development of high-performance and cost-effective batteries. Across a range of applications, energy storage using Li-ion batteries are an essential component in Net Zero strategies. However, these batteries are not without their limitations and face various degradation mechanisms that can impact their performance and safety. As the demand for more reliable and efficient batteries grows, it becomes crucial to understand these degradation mechanisms and develop strategies for improving the design and operation of Lithium-ion batteries (LIBs). Ongoing research aims to develop advanced battery technologies with higher energy density, faster charging rates, and improved safety. Materials innovation, novel electrode designs, and optimized electrolytes are key areas of focus for advancing battery technology.

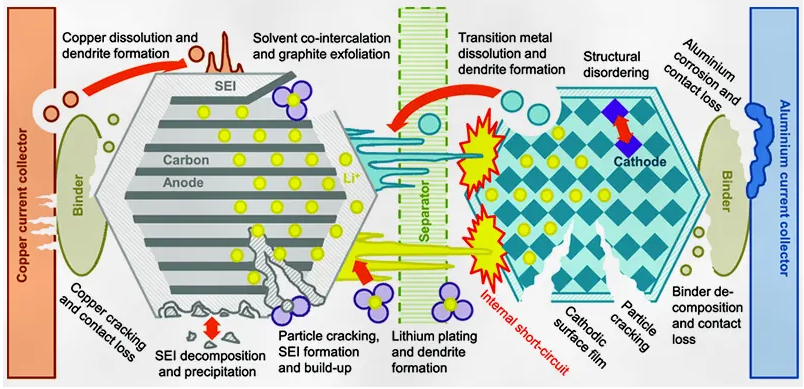

Battery degradation refers to the gradual loss of performance and capacity that occurs over time as a battery is subjected to charge and discharge cycles. Several factors contribute to battery degradation, impacting the overall lifespan and efficiency of the battery. Understanding the degradation mechanisms and performance limitations of commercial batteries is crucial for improving their reliability, safety, and overall performance. Studying the degradation mechanisms and performance limitations of commercial batteries can provide valuable insights into their behaviour and help identify ways to improve their design and operation. The safety of commercial batteries can be also improved by identifying potential failure modes and developing strategies to prevent or mitigate them. [1-4]

The failure of the electrochemical cell, consequently leading to a decrease in the capacity and power fading, does not arise from a single mechanism. Therefore, destructive phenomena acting on both the positive, negative electrode and affecting the cationic lithium are all sources of degradative processes.

Degradation mechanisms in Lithium-ion cell. Reproduced from [7].

Batteries common analysis

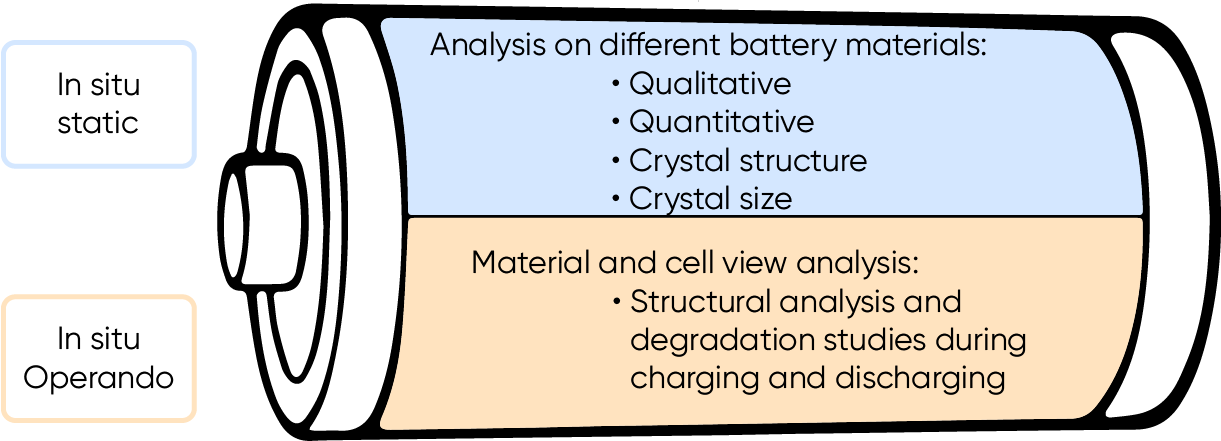

In situ and ex situ studies are two common experimental approaches used in battery research to investigate the behaviour and properties of battery materials. Ex situ studies involve conducting experiments on battery materials or components that have been removed from the battery cell and analysed in a separate environment or under static conditions. In situ studies involve conducting experiments or measurements on battery materials in their original environment without altering the battery. Techniques like X-ray diffraction (XRD), scanning electron microscopy (SEM), transmission electron microscopy (TEM), and spectroscopic methods are commonly used in ex situ and in situ studies to analyse the structural characteristics of electrode materials, electrolytes, and interfaces. In operando studies involve conducting experiments or measurements on battery materials or devices while they are actively operating or undergoing specific electrochemical processes, such as charging, discharging, or cycling. XRD and Computed Tomography (CT) are common techniques to analyse batteries in operando.

In situ-static batteries analysis

Static studies in battery research involve analysing battery materials and components under fixed or equilibrium conditions, providing valuable information on the initial state, structure, and properties of the materials. While static studies do not capture dynamic changes during battery operation like in situ operando studies, static studies are used to characterize the initial state of battery materials before cycling begins. This includes analysing the crystal structure, chemical composition, morphology, and electrochemical properties of electrodes, electrolytes, and interfaces. Static studies provide detailed information on the physical and chemical properties of battery materials, such as lattice parameters, phase compositions, surface morphology, porosity, conductivity, and electrochemical activity. These properties influence the performance and stability of batteries. These studies help identify the different phases present in battery materials and determine their distribution, stability, and role in electrochemical processes. By conducting static studies on battery materials, researchers can assess the suitability of different electrode formulations, electrolyte compositions, and interface engineering strategies for improving battery performance, efficiency, and durability.

By combining static studies with in situ and in operando techniques, researchers can gain a comprehensive understanding of battery materials and systems, from their initial characteristics to their behaviour under dynamic operating conditions. This approach is essential for advancing battery technology, addressing degradation mechanisms, and developing high-performance energy storage solutions for diverse applications.

In situ in Operando batteries analysis

Operando studies, which involve real-time monitoring of system behaviour under typical operating conditions, are pivotal in battery research. By observing electrochemical and mechanical changes during cycling, operando studies unveil fundamental insights into battery performance and degradation. In situ operando studies, specifically, focus on monitoring battery behaviour during cycling to analyse aging and degradation processes in battery materials and devices.

In situ static and operando studies outputs.

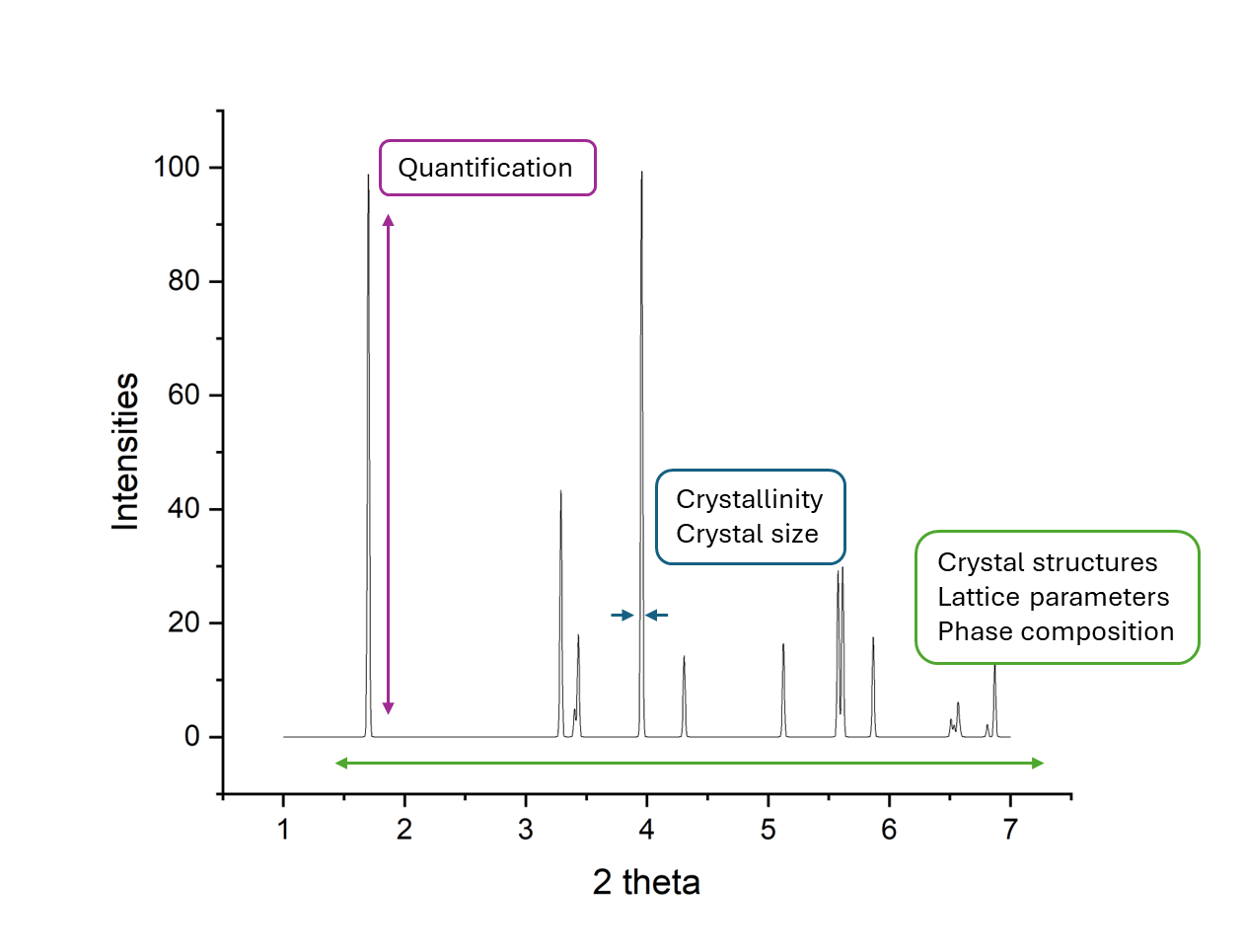

X-ray diffraction (XRD) is a powerful analytical technique used to study the crystallographic structure of materials. In the context of batteries, XRD is employed for in operando analysis coupling the diffraction instrument with a potentiostat, to monitor structural changes during charge and discharge cycles. XRD relies on the interaction of X-rays with the crystal lattice of a material. When X-rays strike a crystalline sample, they are diffracted at specific angles based on the spacing of atomic planes within the crystal lattice. By measuring the angles and intensities of the diffracted X-rays, valuable information about the crystal structure, phase composition, and lattice parameters of the material can be obtained. In the study of battery materials, XRD is crucial for understanding the structural evolution of electrodes during electrochemical processes. By performing in operando XRD measurements, researchers can track changes in the crystal structure of electrode materials as lithium ions intercalate and de-intercalate during charge and discharge cycles.2,5

Diffractograms provides valuable information about the structural properties, phase composition, and changes in battery materials during charge/discharge cycles. The peaks in the diffractogram provides information about the crystal structure, lattice parameters, and symmetry of battery materials.

- Changes in the crystal structure can indicate stress, strain, or phase transitions during cycling.

- XRD peak broadening can be used to estimate the particle size and distribution of active materials in batteries. Changes in peak shapes and positions can reveal variations in particle morphology.

- The intensity of XRD peaks can indicate the degree of crystallinity of battery materials. Changes in peak intensities reflect variations in the ordering and packing of atoms in the crystal lattice.

- Changes in lattice parameters, peak shifts, and peak intensities in XRD patterns provide insights into the intercalation and deintercalation of ions (e.g., Li ions) in electrode materials during cycling.

Diffraction pattern and peaks properties.

XRD data collected during in operando experiments can be analysed using techniques such as Rietveld refinement.6 This method allows for the quantitative determination of phase compositions, lattice parameters, and crystallographic changes in the material. Automated batch mode evaluation is often employed for efficient analysis of large datasets obtained from multiple charge/discharge cycles.

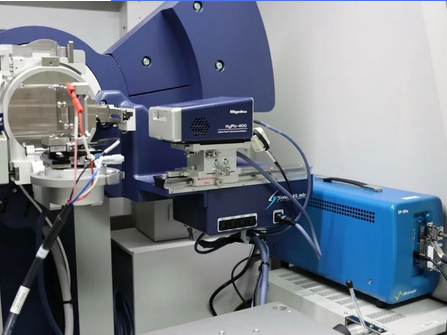

Setting up an experiment for in operando XRD analysis of battery involves several key steps to ensure accurate data collection and meaningful insights into the structural changes occurring during charge and discharge cycles. At Biologic, we combined the use of a high-quality X-ray diffractometer equipped with the necessary components for in operando analysis, such as a Bruker’s D8 ADVANCE XRD, Malvern’s Empyrean X-ray diffractometer and Rigaku’s SmartLab, with our SP-50e/150e potentiostats.

XRD instruments and potentiostats set up for in situ operando analysis with Bruker’s D8 ADVANCE XRD and Rigaku’s SmartLab.

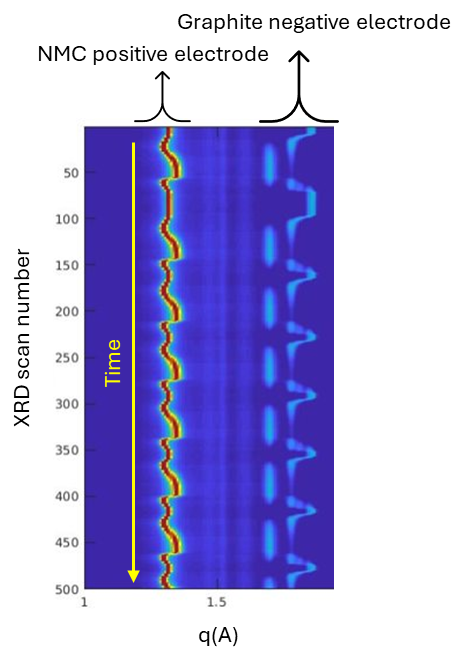

With this set up researcher are able to perform in operando XRD measurements on pouch and coin cells during charge and discharge cycles to monitor structural changes in the electrode materials. For example, by collecting diffraction patterns during cycling, it is possible to track phase transformations and lattice parameter variations. At the end of the experiment, from diffraction patterns collected it is possible to extract phase compositions, lattice parameters, and structural changes in the battery materials. This can lead to gain insights into the mechanisms of battery degradation, such as electrode expansion/contraction, electrolyte interactions, and cycling-induced structural modifications.

Evolution of peaks in the diffractogram of a cell. It is showed the evolution of NMC positive electrode and graphite negative electrode over time.

Conclusion

X-ray diffraction is a valuable tool for studying the structural properties of battery materials, and in operando XRD analysis offers a unique perspective on the dynamic changes that occur within electrodes during electrochemical cycling. XRD analysis plays a crucial role in elucidating the structural dynamics and behaviour of battery materials, guiding the design and optimization of next-generation energy storage devices.

References

- Broussely, M. et al. Main aging mechanisms in Li ion batteries. J. Power Sources 146, 90–96 (2005).

- Birkl, C. R., Roberts, M. R., McTurk, E., Bruce, P. G. & Howey, D. A. Degradation diagnostics for lithium ion cells. J. Power Sources 341, 373–386 (2017).

- Liu, D. et al. Review of Recent Development of In Situ/Operando Characterization Techniques for Lithium Battery Research. Adv. Mater. 31, 1–57 (2019).

- Vetter, J. et al. Ageing mechanisms in lithium-ion batteries. J. Power Sources 147, 269–281 (2005).

- Zhou, Y. N. et al. High-Rate Charging Induced Intermediate Phases and Structural Changes of Layer-Structured Cathode for Lithium-Ion Batteries. Adv. Energy Mater. 6, 1–8 (2016).

- Cusker, L. B., Von Dreele, R. B., Cox, D. E., Louer, D. & Scardi, P. (1999). J. Appl. Cryst. 32, 36-50.

- Pastor-Fernández C, Yu TF, Widanage WD, Marco J. Critical review of non-invasive diagnosis techniques for quantification of degradation modes in lithium-ion batteries. Renewable and Sustainable Energy Reviews. 2019;109: 138-159, ISSN1364-0321.