Sustainable batteries: Recycling and 2nd life

Latest updated: October 8, 2024Introduction

The current ecological situation is pushing humankind to rethink their standards for energy consumption. The storage of electricity is one of the main challenges and if the energy must come from sustainable sources, the energy storage devices also need to be designed keeping in mind sustainability as far as possible – from the choice of materials and production ways to the end-of-life of the storage device. In the past few years, this topic has become of great interest, and governments legislate to support the transition. In June 2023, for example, the European Parliament made new rules for the design, production, and waste management of batteries [1]. The aim is to have circular economic legislation that covers the entire life cycle of the product.

What to do with “spent” energy storage devices? The example of Lithium-Ion Batteries (LIBs)

The most effective way to avoid waste and environmental damage is prevention. Indeed, the end-of-life of the battery should be thought from the development steps of the battery cells and even from the development of products to reduce the required size of the battery. However, what should be done with the existing “spent” energy storage devices, whether they have been designed to reduce their environmental impact or not?

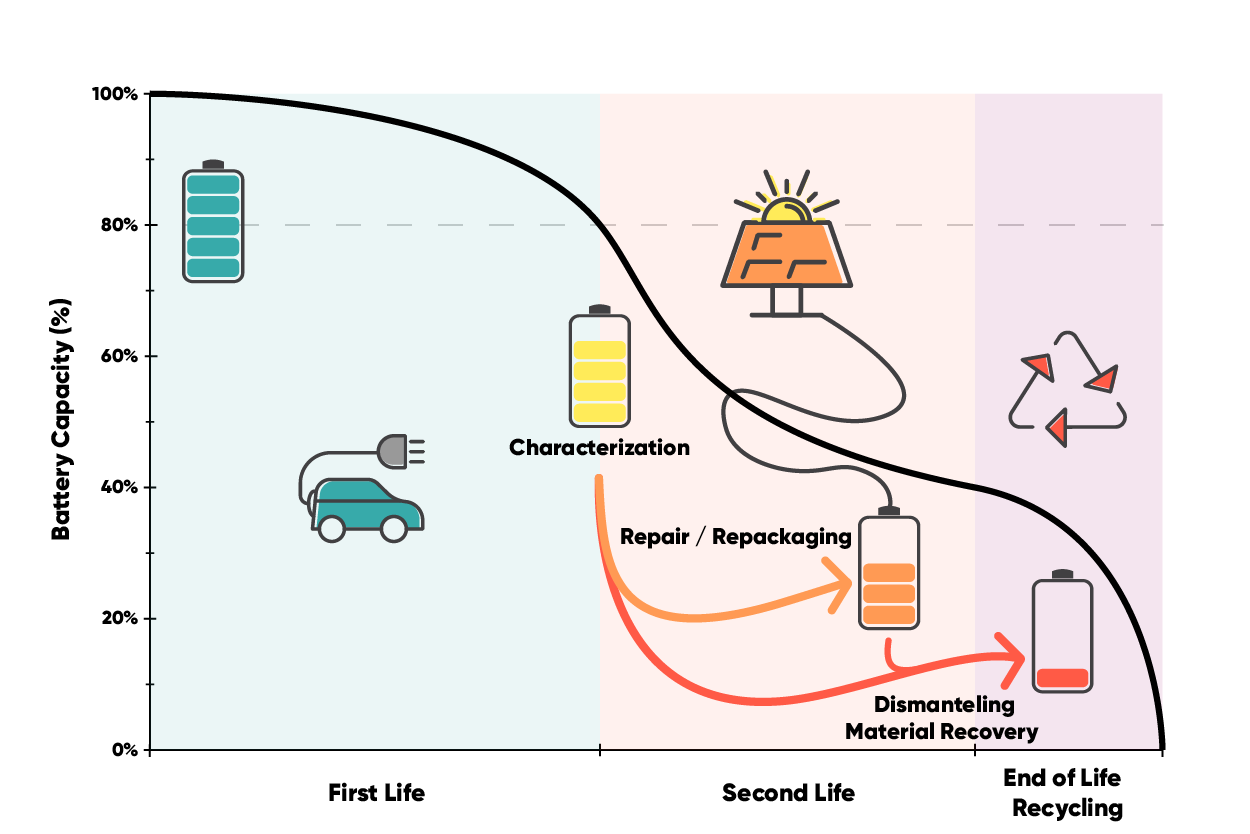

For LIBs, four solutions can be highlighted. Some are less desirable for the environment than others: re-using (finding a second usage), recycling (extracting valuable materials from the battery to use them again to build new devices), recovery (using some materials of batteries as fuel), and disposal (landfills or incineration) [2]. The characterization of batteries is essential once they have reached the end of their life. It allows sorting out the batteries that can be converted and reused, those that must be dismantled for recycling, and those that don’t have value anymore.

The recycling and re-using of batteries are the most preferable solutions for the environment because they result, among other measures, in reducing the quantity of metal to be extracted from mines, the impact of manufacturing, and the wastes caused by end-of-life batteries.

What is battery recycling?

Recycling a battery starts with dismantling the battery to separate and recover materials. Some of those materials, mostly metals, can be re-used to produce new batteries. Plastics are often used as fuel and other materials such as lithium, graphite, or manganese are not considered in the balance at the moment and are wasted [2].

Why do we talk about re-using a battery? What is a 2nd life battery?

Let’s take the example of the Electric Vehicles (EVs) batteries. It all starts because of one rule: batteries must be retired when their capacity is reduced by 20% compared to the capacity at the beginning of their life [2]. That means that 80% of the capacity (see glossary of terms) remains in the battery and most of the time, the batteries are not damaged. The point of re-using the battery is to use those batteries for other applications that require less energy so they can operate safely. This offers a 2nd life to a “spent” battery.

Two solutions are viable then [3]:

- Repurposing when the whole pack is used as it was in another application;

- Refurbishment of packs when the pack is disassembled to keep only the best cells which are reconditioned and repacked in new modules.

The issue is that not all batteries can be candidates for the 2nd life solution. Some of them are too damaged (electrolyte leakage, mechanical damage, over-discharge, …) to be redirected to another application with lower required energy. The damage is not always visible at first sight but the specialized manufacturers in the reconditioning of batteries are responsible for the safety of the batteries they sell for a 2nd life. Characterization tools are essential to obtain values of characteristic quantities that will help in classifying batteries. Usually, they do not have access to the background of the packs they receive. Characterization tools are even more essential in that case.

Characterization techniques for single-cell

The characterization of batteries that have reached the end of their life is a changing and growing area. The range of battery technology is wide, and the aging conditions of the cells and the packs are often unknown by the industrials who gather the end-of-life batteries. It makes characterization very difficult, but it remains crucial for the field. This is evidenced by the fact that governments are pushing for more transparency and open knowledge about batteries with the introduction of a digital passport for batteries in European laws for example [4]. It will facilitate the classification of batteries after their first usage and allow for more precise and efficient characterizations.

The paragraph below gives a non-exhaustive list of the existing characterization methods. These methods on their own will not give a strict evaluation of the battery. They are only reliable if they are repeated on a large number of battery cells and/or battery packs to allow the implementation of models and determine the relevant criteria to classify the batteries.

- The determination of the internal resistance (see series of articles on internal resistance https://biologic.net/topics/internal-resistance-series-part-i-what-is-internal-resistance-in-a-battery/). An increase in the internal resistance may indicate that the battery is close to the end of its life or dead. This determination can be done using AC or DC methods.

- The Electrochemical Impedance Spectroscopy (see article https://biologic.net/topics/what-is-eis/ ) gives a detailed description of the phenomena at stake in the battery. Thus, it can be used to identify the frequency of interest where the increase or decrease of the impedance is a symptom of the degradation of the battery.

- The estimation of the SoH (see article https://biologic.net/topics/battery-states-state-of-charge-soc-state-of-health-soh\) with a constant Voltage Analysis during CC-CV Charge. This method is based on the observation of the increase of chemical reactions (intercalation process of the lithium into the graphite negative electrode) occurring during the constant voltage step (5% for fresh cells against 32 to 45% for degraded cells) [5].

- The estimation of the SoH by incremental capacity analysis (see article https://biologic.net/topics/investigating-battery-ageing-using-differential-capacity-analysis-dca/ ). In this case, the dQ/dV curve is analyzed to observe the degradation process of the battery during cycling.

- The Hybrid Pulse Power Characterization (see definition in the glossary https://biologic.net/topics/interactive-battery-science-glossary-of-terms/). The principle of this technique is based on applying current pulses to highlight the battery’s ability to provide and accept charge over the full range of SoC.

What instrument is needed to characterize batteries for 2nd life?

Pack Characterization

BioLogic offers a wide range of instruments that are well-suited for battery cells and pack characterization studies (insert link to instrument pages. The best choice will mainly depend on:

- The configuration of the pack. What is the number of cells in series, and what is the number of cells in parallel constitutive of the pack? It will influence the current and the voltage needed to run experiments.

- The level of modularity required: do you only want a potentiostat for a single purpose? Or do you wish to use the potentiostat for other applications in your lab? If so, you’ll want the ability to connect boosters or add more channels autonomously. You may also consider modularity as a solution to scale up without needing to buy a completely new system each time.

- The level of integration required: If you need to integrate the potentiostat into a commercial or homemade bench station so you can control the potentiostat from your software, EC-Lab® offers a developer package for OEM integration. You can then use one software for data acquisition and to communicate with your gas station, e.g., synchronize Start/Stop commands or change operating conditions (temperature, pressure, humidity, flow rate…).

Cell characterization within a pack: Stack measurements

Stack measurements (Optimize Pack and Stack Performance with Simultaneous Measurements and Pack and Fuel Cell Stack: Application Note #59) are a great tool for characterization studies dedicated to sorting out battery packs and identifying weak cells. This can be achieved with an Essential range potentiostat (a VSP-3e for example), a high current booster such as the FlexP0012, and SAM-50. It allows controlling and running experiments on the full pack of batteries while monitoring the potential of each cell constituting the pack (if the cells are connected in series). Consequently, it is possible to observe the global state of health of the pack and identify the weak point during only one experiment.

Conclusion

The management of the end-of-life of the battery is key for future developments in the battery field because at the same time it represents an economic and environmental challenge. Industry needs to be organized around this issue to find effective solutions from manufacturing to waste recycling.

References

[1] https://www.europarl.europa.eu/news/en/press-room/20230609IPR96210/making-batteries-more-sustainable-more-durable-and-better-performing, Accessed 24/01/2024.

[2] Dobó, Z., Dinh, T., & Kulcsár, T. (2023). A review on recycling of spent lithium-ion batteries. Energy Reports, 9, 6362-6395. https://doi.org/10.1016/j.egyr.2023.05.264.

[3] https://corporate.enelx.com/en/question-and-answers/what-is-second-life-battery, Accessed 26/01/2024.

[4] https://environment.ec.europa.eu/news/new-law-more-sustainable-circular-and-safe-batteries-enters-force-2023-08-17_en, Accessed 21/02/2024.

[5] Quinard, H., Redondo-Iglesias, E., Pelissier, S., Venet, P. (2019). Fast Electrical Characterizations of High-Energy Second Life Lithium-Ion Batteries for Embedded and Stationary Applications. Batteries, 5, 33. https://doi.org/10.3390/batteries5010033.

Related products